How to get URL link on X (Twitter) App

https://twitter.com/phoennix10/status/1009225009212997633

https://twitter.com/lopezlinette/status/1031914186388004864@lopezlinette 2/ In order to meet their 5k/week commitment, Tesla put untrained interns and employee’s on the line and lowered and probably lowered their quality standards.

https://twitter.com/phoennix10/status/1009786127887183872

https://twitter.com/ElonsPromises/status/10316011088405872642/ They use a lot of red bins which goes against conventional visual systems. Red is usually meant for scrap/quarantined material.

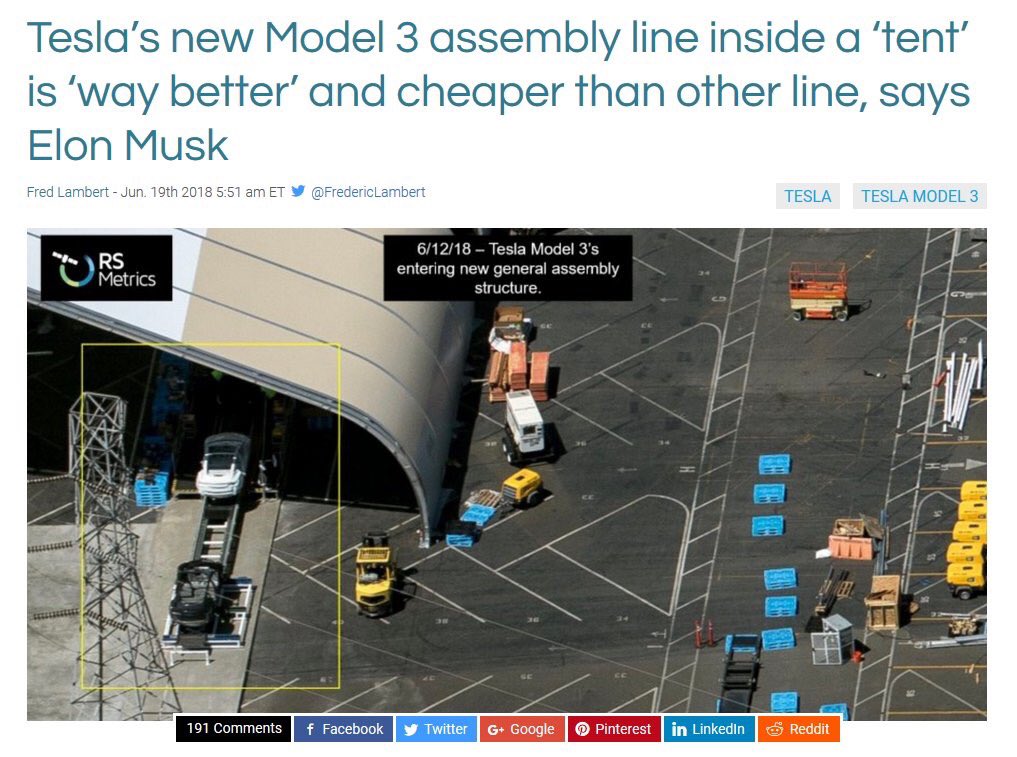

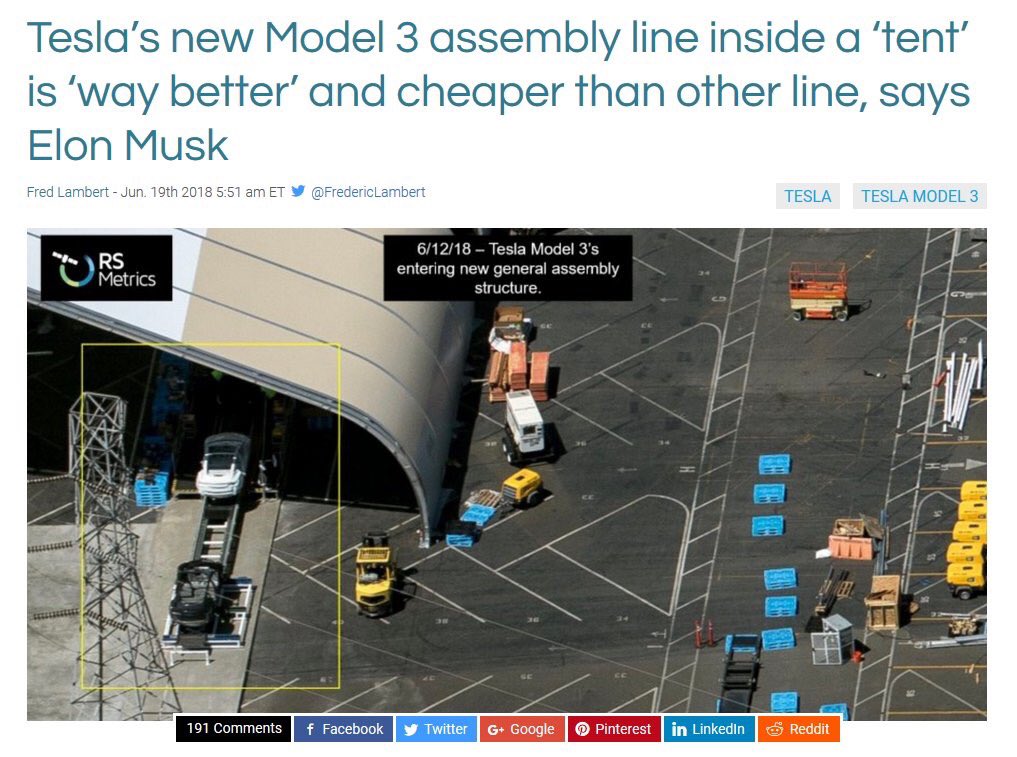

2/ So, they are literally picking up the car and carrier with a forklift from post paint inspection within the factory. Then they are driving it out of the factory over a shitty parking lot, jostling the vehicle body the entire way.

2/ So, they are literally picking up the car and carrier with a forklift from post paint inspection within the factory. Then they are driving it out of the factory over a shitty parking lot, jostling the vehicle body the entire way.